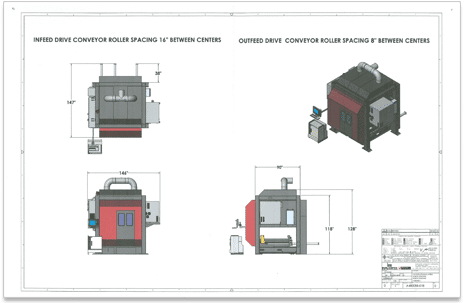

Flexible Configurations for Optimized Operation

The versatility of the PythonX STRUCTURAL eliminates other machines and the maze of transfers and conveyors between those machines. That, coupled with its small footprint, provides remarkable flexibility for laying out a fabrication shop.

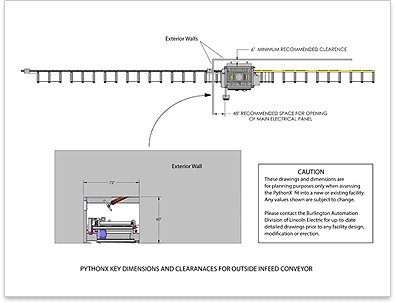

For example, raw materials are often stored outdoors, so the PythonX STRUCTURAL infeed conveyor can be placed outside the building for convenient loading. Sometimes a ‘doghouse’ for the PythonX STRUCTURAL is built inside the larger building to better manage fume extraction and noise.

The images below provide dimensions of equipment and clearances that are valuable when laying out a PythonX STRUCTURAL in a fab shop.