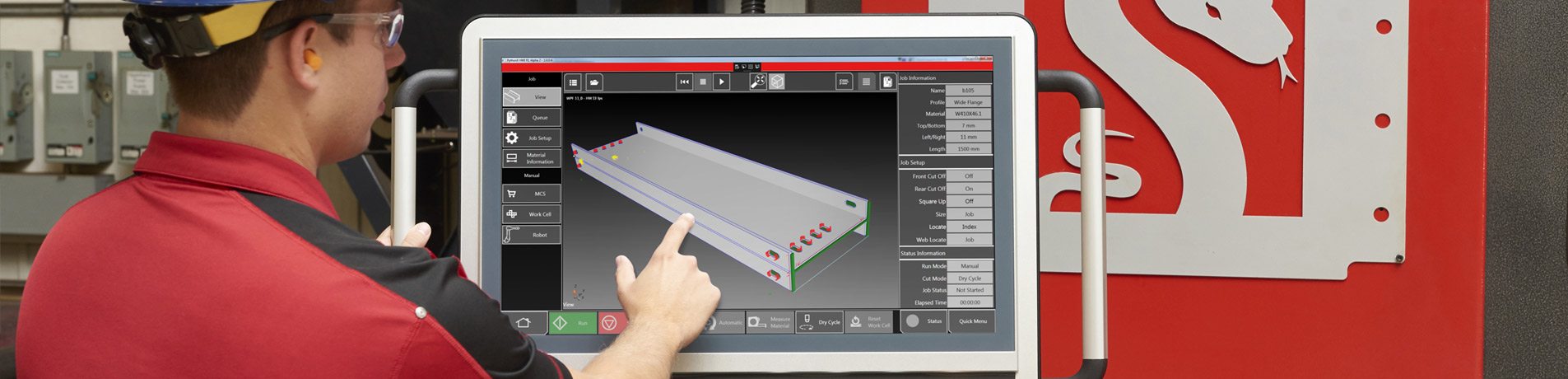

The PythonX STRUCTURAL Difference

How You Benefit

Quickest Return on Investment

- Lowest cost per ton

- Increased revenue per square foot

- Starts paying for itself 4 to 6 months sooner

Fastest Delivery, Installation and Training in the Industry

- Delivered in 4 weeks

- 1 week installation

- 1 week of training

- Fully operational in just 6 weeks from order

Predictable and Sustainable Throughput

- Ability to provide more accurate job estimates

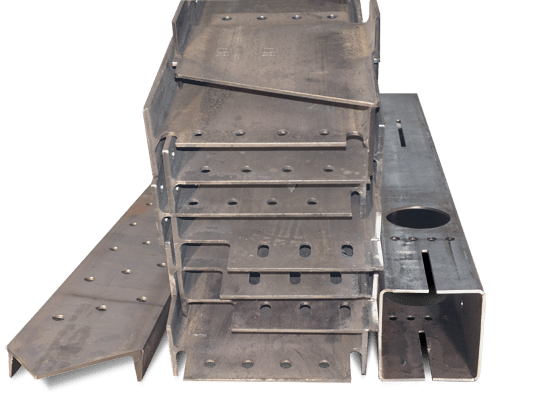

Complex Cutting

- Done automatically, allowing the fabricator to bid on more complex projects

Small Footprint

- Replaces several traditional machines and conveyors

- More room for fitting, welding and painting

- Maximize the productivity of your existing facility’s space

- No need to acquire a larger facility

Safety

- Minimize material handling

- Less stacking and storing of processed material

- Scrap bins allow parts to be extracted without operator entering the cell

- Parts as short as 24″ can be conveyed out of cell, instead of being removed manually

- Auto-stop feature if door is opened during operation

Designed, Built, Supported in North America

- Use highest quality components from best-in-class suppliers with global distribution

- 24/7 access to dedicated support specialists

- Commitment to support every PythonX STRUCTURAL ever built, for the service life of the machine

Be the Lowest Cost per Ton Producer

But, if you pay about the same as your competitor for steel and labor, how do you get to the lowest cost per ton?

You get LEAN.

PythonX STRUCTURAL is the lean machine that lets you do more with less:

- Less Time per Piece

- Less Material Handling

- Less Inventory

- Less Waiting

- Less Waste

- Less Space

- Less Overhead

- Less Programming

- Less Errors

- Less Scrap

We’ve been able to pass along to our customers the savings of reduced time in the shop, so we’re getting more jobs because we’ve been able to reduce our operating costs.

PythonX instantly automates the growing fabrication shop, providing a level of CNC sophistication that would otherwise take years and millions of dollars to reach with traditional fabrication equipment. Smaller fabrication shops of 10,000 sq. ft. and 10 to 20 employees are now using PythonX as their foundation for growth.

PythonX has made us more competitive. We can take on larger projects having a smaller margin for error. And because errors are costly, it has increased our margins on these types of projects.

Ensuring Your Business Thrives, Day-by-Day, Year After Year

Everyday you push the limits to get jobs done on time and under budget. At Burlington Automation, we understand. That’s why for over a decade, we have focused on developing the ideal solution for structural steel fabricators. The result: over 380 PythonX STRUCTURAL systems processing steel around the globe. And more being added everyday.

Sure, there are imitators, but PythonX STRUCTURAL has proven time and again to be the most capable technology in the structural steel fabrication space. It ensures your business thrives by delivering consistent performance that meets the challenges and time constraints of today’s construction industry. It also ensures peace of mind through future-proof upgrades and a record of reliability that allows us to confidently offer the longest warranty in the industry.

As a division of Lincoln Electric, we are part of a world class manufacturing and automation leader that develops solutions to make our customers more productive and successful. We invite you to visit our facility in Hamilton, Ontario Canada, to meet our team, and to enter a partnership that will help ensure your success for years to come.

We installed the PythonX system in the summer of 2015 and it immediately began opening new doors for us. With PythonX, we bid and get jobs that we never would have gone after in the past.

PythonX STRUCTURAL is highly standardized and much in demand so we always have machines in process. The result: we offer PythonX STRUCTURAL with 4 week delivery. That matters when you bid or win a job where PythonX STRUCTURAL can greatly improve your margins. And with only 5 days needed to install, you can be up and running within 6 weeks of order.

PythonX has eliminated multiple work stations, saving us massive amounts of space and streamlining our material handling. We have less material prep, fewer errors and QA is more efficient.

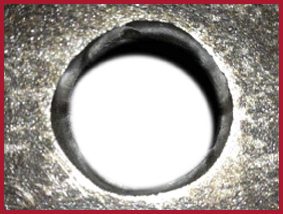

Best In Class Cut Quality And Accuracy

Poor hole quality and cut finish can lead to failed inspections, lost jobs, and a damaged reputation. But PythonX STRUCTURAL pioneered robotic plasma hole technology and has been producing the undisputed best bolt holes and cuts in the industry for many years. PythonX STRUCTURAL bolt holes have been lab-tested and are AISC/EN1090 compliant.

Bolt Holes

PythonX STRUCTURAL automatically tilts the cutting torch and uses a patented cutting process resulting in a perfectly straight through hole that is NEARLY TAPERLESS.

PythonX STRUCTURAL

Competitor

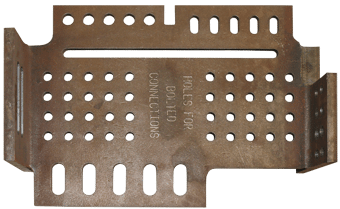

Slots

PythonX STRUCTURAL cuts slots and other shapes to the exact specified dimensions allowing for perfect fitup.

PythonX STRUCTURAL

Competitor

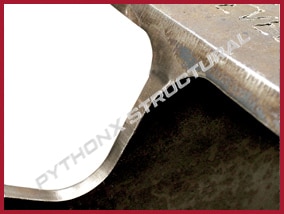

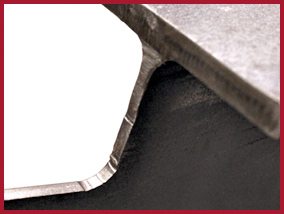

Copes

The PythonX STRUCTURAL copes are produced with a mirror like finish and a smooth corner radius. No touch-up is required.

PythonX STRUCTURAL

Competitor

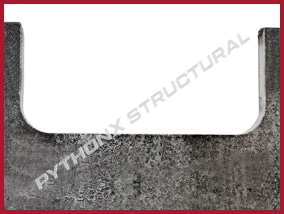

Notches

Notches, cutouts and flush cuts made by PythonX STRUCTURAL are smooth and do not require additional grinding or shaping. Their perfect fitup also results in less welding.

PythonX STRUCTURAL

Competitor

Compare Beam Fabrication Machines

70 to 80% of the beams that leave your shop have more than just bolt holes. It takes only 5 to 10 minutes to drill the bolt holes with a beam line, but there’s anywhere from 20 to 120 minutes of labor and machine time to make the copes, bevels, slots, notches, marking, etc. needed for a finished beam. So the average beam leaving your shop has 5 minutes of drilling and 1 hour of manual fabrication work in it.

Beams that leave a PythonX STRUCTURAL average 10 minutes total fabrication time. That’s a savings of at least 45 minutes per beam.

And that’s just the time savings. PythonX STRUCTURAL improves your entire operation, as it nearly eliminates all material handling, machine programming, tooling, rework and the redundant single-purpose machines you’re probably using now . . . like a beam drill line.

| Machine Capability | Single Spindle Beam Drill Line | Three Spindle Beam Drill Line With Band Saw | PythonX STRUCTURAL |

|---|---|---|---|

| Produces Quality Bolt Holes | YES | YES | YES |

| Maximum Hole Diameter | 2 in. (50 mm) | 2 in. (50 mm) | 24 in. (609 mm) |

| Produce Layout Marks for Clips & Stiffeners | LIMITED | LIMITED | YES |

| Downloads from Design/Detailing Software (TEKLA, SDS/2, StruCAD, ProSTEEL, AUTOCAD) | YES | YES | ANY SHAPE |

| Time to Cut-to-Length one W24 x 100 | INCAPABLE | 5 MINUTES | 1 min 15 sec |

| Automatic Part Handling (set it and forget it) | FLIP MANUALLY | YES | YES |

| Cut Copes with CNC Accuracy | INCAPABLE | INCAPABLE | YES |

| Make Cutouts for Bracing & Knife Connections | INCAPABLE | INCAPABLE | YES |

| Text Scribing - any size | INCAPABLE | INCAPABLE | YES |

| Fabricate Complete Stair Stringers (including Tread layout) | INCAPABLE | INCAPABLE | YES |

| Miter Cut | INCAPABLE | COSTLY OPTION | YES |

| Cut Slots & Any Other Shapes | INCAPABLE | INCAPABLE | YES |

| Weld Prep Bevel Cut | INCAPABLE | INCAPABLE | YES |

| Rip I-Beams into T-Beams | INCAPABLE | INCAPABLE | YES |

| Tool Change Required | YES | YES | NEVER |

| Overall Production Output | SLOW | AVERAGE | FASTEST |

| Price | LOWEST | HIGHEST | MID RANGE |

| Machine Capability | Single Spindle Beam Drill Line | Three Spindle Beam Drill Line With Band Saw | PythonX |

| Produces Quality Bolt Holes | YES | YES | YES |

| Maximum Hole Diameter | 2" (50 mm) | 2" (50 mm) | 24" (609 mm) |

| Produce Layout Marks for Clips & Stiffeners | LIMITED | LIMITED | YES |

| Downloads from Design/Detailing Software (TEKLA, SDS/2, StruCAD, ProSTEEL, AUTOCAD) | YES | YES | ANY SHAPE |

| Time to Cut-to-Length one W24 x 100 | INCAPABLE | 5 MINUTES | 1 min. 15 sec. |

| Automatic Part Handling - set it and forget it | FLIP MANUALLY | YES | YES |

| Cut Copes with CNC Accuracy | INCAPABLE | INCAPABLE | YES |

| Make Cutouts for Bracing & Knife Connections | INCAPABLE | INCAPABLE | YES |

| Text Scribing - any size | INCAPABLE | INCAPABLE | YES |

| Fabricate Complete Stair Stringers (including Tread layout) | INCAPABLE | INCAPABLE | YES |

| Miter Cut | INCAPABLE | COSTLY OPTION | YES |

| Cut Slots & Any Other Shapes | INCAPABLE | INCAPABLE | YES |

| Weld Prep Bevel Cut | INCAPABLE | INCAPABLE | YES |

| Rip I-Beams into T-Beams | INCAPABLE | INCAPABLE | YES |

| Tool Change Required | YES | YES | NEVER |

| Overall Production Output | SLOW | AVERAGE | FASTEST |

| Price | LOWEST | HIGHEST | MID RANGE |

Since introducing the PythonX to our shop, we’ve substantially increased our production. This is our first and only beamline and it has greatly benefited our shop, increasing quality and output.

Yes, people make mistakes: in reading drawings, in layout, in programming and in manual cutting. PythonX STRUCTURAL eliminates these sources of human error. With the right drawing file and the right piece of steel, it will produce the right part every time. You won’t believe how much that can improve your margins.

The PythonX Structural System has helped us increase production by 300% since it was installed. I have no idea how we would be able to get this work out without this machine.