More Than A Machine

PythonX STRUCTURAL has created a NEW STANDARD in the way you think about running a fabrication shop.

Compared to traditional machines, PythonX STRUCTURAL:

- Uses a fraction of floorspace

- Needs only minutes of processing time

- Requires Only One Operator & No Programming

- Offers complete fabricating capability for a fraction of the price

Customer Success Stories

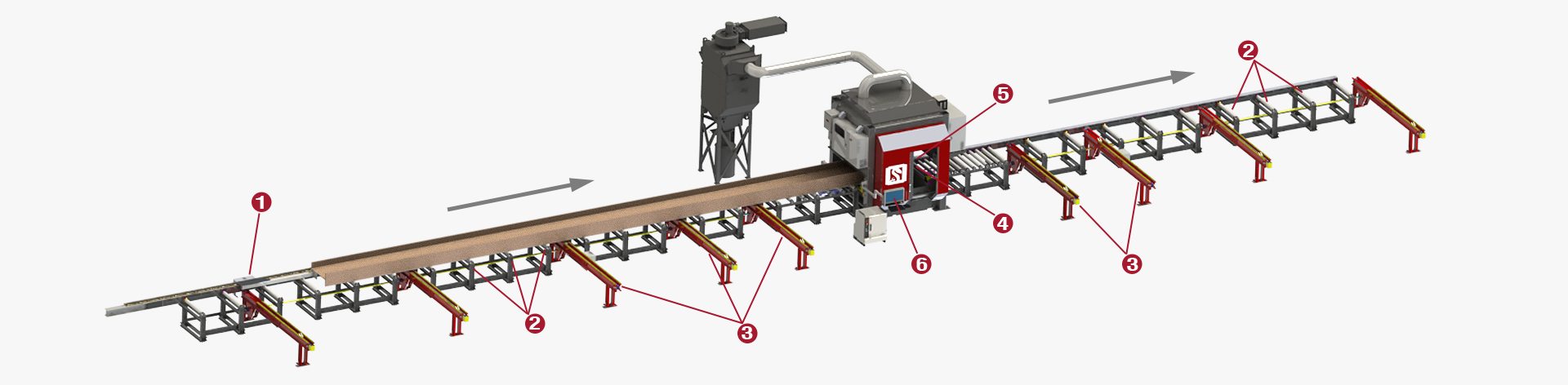

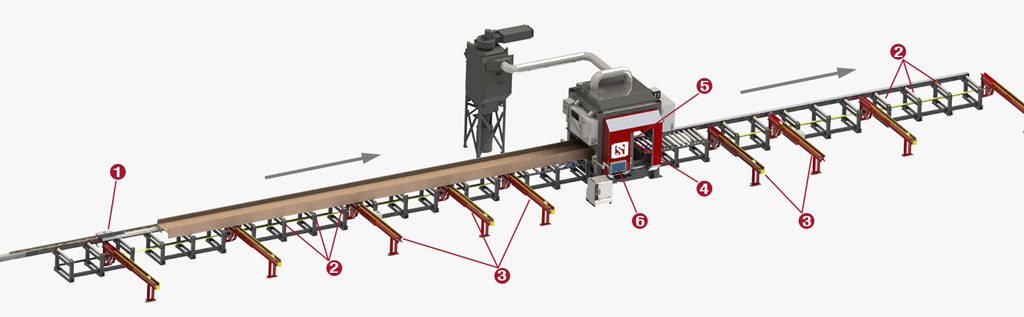

PythonX STRUCTURAL Layout

Measuring Cart

The measuring cart relays the exact position of the work piece to the robot.

- More accurate than pinch rolls, which can slip

- Measures and displays full length of the beam – not possible on pinch roll systems

Infeed/Outfeed Conveyors

Precision machined rollers with no flat spots for ultimate accuracy.

- 4 in. (101.6mm) diameter on heavy duty frames

- Built to last with oversized 7.5 hp motors – most others use 2.0 hp

Cross Transfers

Accumulate and transfer material for Infeed and Outfeed conveyors (optional feature).

- Reduces material handling, increases output

- Heavy duty motor and gear reducer controlled by variable frequency drive

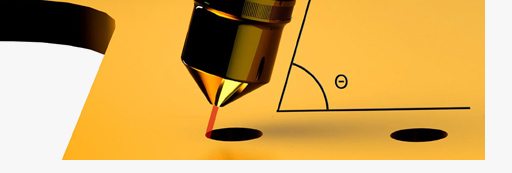

High Definition Torch

High Definition Plasma technology aligns and focuses the plasma arc, improving arc stability and energy for more precise cutting.

- Completely automatic gas and kerf control

- PATENTED hole taper compensation and advanced bevel tuning

Multi-Axis Robotic Arm

Tuned twice for absolute best-in-class accuracy and least cut-path following error.

- Complete with collision detection

- Stronger, with a higher payload to minimize vibration and sway

NEW! Operator Control System

New features and capabilities let you get more done, more quickly and easily.

- 24in (61 cm) HMI with intuitive touch screen

- Ergonomic handles allow easy movement into the optimum position for any operator

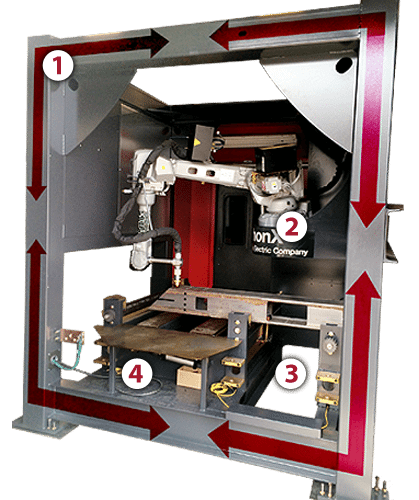

1. ONE PIECE WELDED BOX FRAME

Heavy, strong and designed to be extremely rigid. The uni-body welded frame provides the most stable, vibration free foundation for the cutting system.

2. FIXED STATIONARY ROBOT BASE

A fixed base welded to the box frame lets PythonX STRUCTURAL use only the robot motion to perform cutting – no additional axes of motion to add vibration, backlash or sway that degrade cut quality.

3. UNDERSIDE CUTTING

The underside cuts are performed in a separate zone where no scrap pieces fall and no crash can occur.

4. CUTS AND SEVERS

All sever operations occur in this zone, with ample room for endcuts and scrap to accumulate without having to worry about crashes.

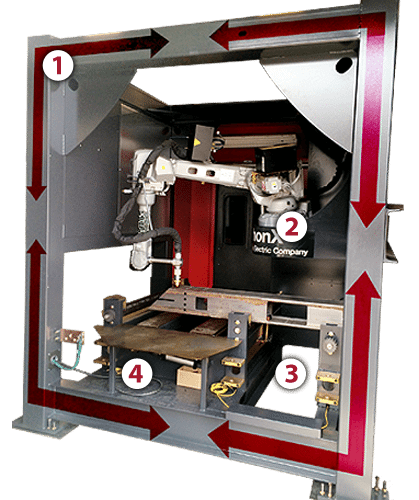

Built For

Maximum

Precision

Heavy, strong and designed to be extremely rigid. The uni-body welded frame provides the most stable, vibration free foundation for the cutting system.

2. FIXED STATIONARY ROBOT BASE

A fixed base welded to the box frame lets PythonX use only the robot motion to perform cutting – no additional axes of motion to add vibration, backlash or sway that degrade cut quality.

3. UNDERSIDE CUTTING

The underside cuts are performed in a separate zone where no scrap pieces fall and no crash can occur.

4. CUTS AND SEVER

All sever operations occur in this zone, with ample room for endcuts and scrap to accumulate without having to worry about crashes.

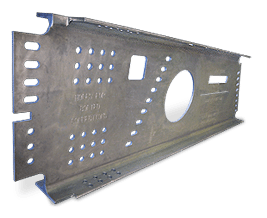

4-Side Tube Cutting

PythonX STRUCTURAL adds a fixed robotic arm to cut the tube underside and process all 4 sides in one pass. The only robotic plasma to perform 4-side cutting and beveling without mounting the robot on a moving or rotational base, which sacrifices cut quality.

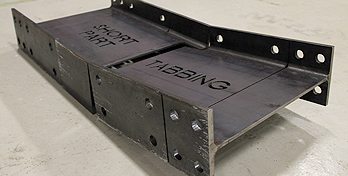

Part Tabbing

Part tabbing allows for shorter structural steel parts to remain attached to the main beam for easier handling and storage. With PythonX STRUCTURAL, the type of tab and tab length is programmable by the operator.

Shorter Piece Transfer

For added flexibility, PythonX STRUCTURAL has advanced software combined with closer conveyor roller spacing to allow for short parts to be transferred from the cutting area after a cut to length operation. No need to open or reach into the cutting cabinet.

Larger Work Envelope

The expanded robot cutting area allows for more features to be cut at once. That reduces material indexing, leading to even lower total processing time per piece.

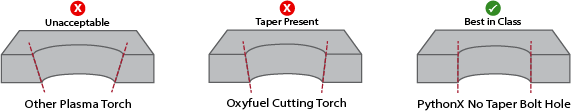

Patented Bolt Hole Process

Only PythonX STRUCTURAL employs a patented process that tilts the torch, instantaneously changes speeds and uses sophisticated software algorithms to produce straight through holes that are NEARLY TAPERLESS.